An Overview of Industrial Surge Protection

In the realm of industrial operations, protecting sensitive electronic equipment is paramount. Industrial Surge Protection is a critical component in defending against the catastrophic impacts of power surges. These surges can originate from external events such as lightning strikes or from internal activities like equipment switching. Implementing effective Industrial Surge Protection measures not only prolongs the life of your equipment but also minimizes downtime and reduces maintenance costs.

As someone with over 20 years in the industry, I’ve witnessed firsthand the transformative power of effective surge protection. Companies that integrate these solutions often see a significant return on investment through decreased operational disruptions and enhanced equipment longevity.

The Importance of Surge Protection for Businesses

Businesses, especially those reliant on complex machinery and sensitive data, cannot afford the risks associated with power disruptions. Industrial Surge Protection serves as a safeguard, ensuring continuity in operations. By preventing surges from reaching critical systems, businesses not only protect their investments but also uphold their reputation for reliability.

Consider a manufacturing plant that halts production due to an unexpected surge. The financial implications extend beyond immediate repair costs, affecting production schedules and client commitments. With proper Industrial Surge Protection, these risks are greatly mitigated, ensuring productivity remains uninterrupted.

Furthermore, many insurance providers now recognize the value of surge protection in risk assessment, potentially lowering premiums for businesses that prioritize these safety measures.

Types of Industrial Surge Protection

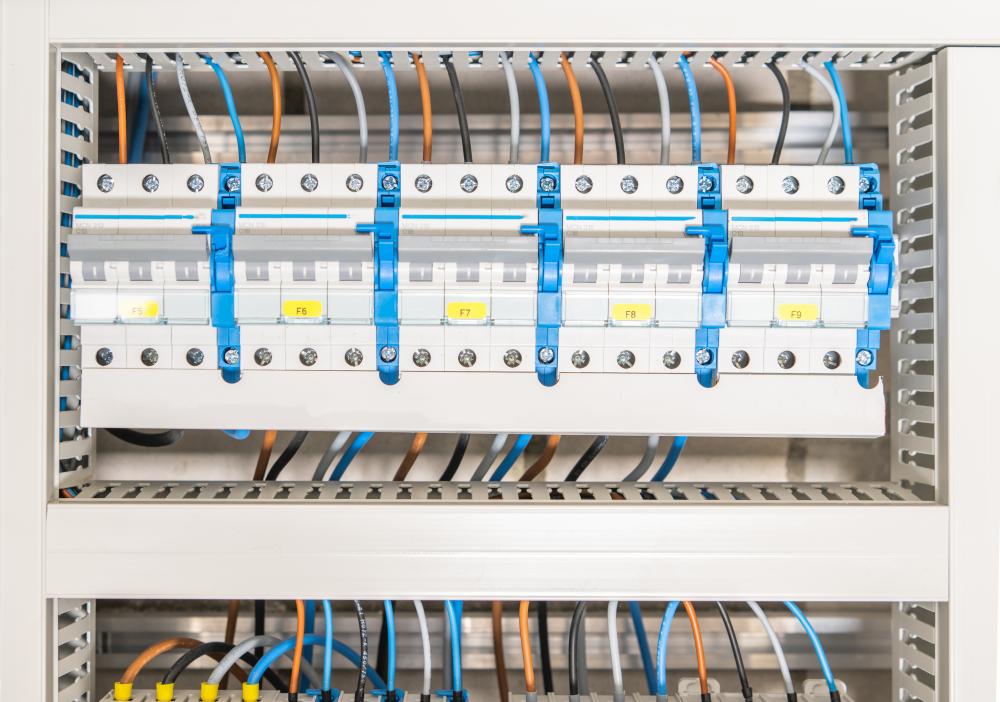

Industrial Surge Protection comprises various components, each tailored to specific needs:

- AC Surge Protectors: Essential for defending against surges in alternating current, these devices are commonly used in large-scale settings.

- DC Surge Protectors: These protect direct current applications, crucial for industries relying on DC power sources.

- Signal Line Surge Protectors: They shield communication and data lines from electromagnetic interference and surges.

- Surge Monitoring Systems: These systems provide real-time data on surge events, allowing for proactive maintenance and adjustments.

How to Set Up Industrial Surge Protection in 5 Steps

Setting up Industrial Surge Protection involves careful planning and execution. Here’s a step-by-step guide:

- Assessment: Begin by assessing your facility’s unique risks and vulnerabilities.

- Selection: Choose the appropriate surge protection devices based on your assessment.

- Installation: Work with qualified professionals to ensure correct installation.

- Integration: Integrate surge protection with existing monitoring systems for optimal performance.

- Maintenance: Regularly inspect and maintain your surge protection systems to ensure ongoing efficacy.

These steps, while seemingly straightforward, require attention to detail and a deep understanding of the facility’s operational dynamics. As a seasoned professional, I advocate for a thorough initial assessment to tailor solutions that address specific industrial challenges.

Key Advantages of Industrial Surge Protection

The deployment of Industrial Surge Protection offers numerous benefits:

Firstly, it dramatically reduces the incidence of downtime due to electrical disturbances, thereby enhancing productivity. Secondly, it extends the operational life of equipment, offering long-term financial benefits by reducing the need for frequent replacements.

Another advantage is the peace of mind it provides to business owners and facility managers, knowing that their critical infrastructure is shielded from unexpected power surges. In this fast-paced industrial landscape, having a reliable surge protection strategy is not just beneficial; it is essential for maintaining competitive advantage.

I’ve seen companies transform their operational efficiency by incorporating comprehensive surge protection frameworks, and the results often speak for themselves in terms of enhanced reliability and customer satisfaction.

What Qualifies as an Industrial Surge Protection Emergency?

An Industrial Surge Protection emergency occurs when an unexpected surge threatens the integrity of equipment and interrupts operations. Immediate action is required to prevent damage and downtime.

In such scenarios, businesses should have a response plan in place that includes immediate shutdown protocols and access to surge protection specialists who can quickly rectify the situation. Proactivity in establishing these protocols is crucial, as it ensures swift recovery and minimal financial loss when emergencies arise.

What are the key benefits of implementing industrial surge protection systems?

Industrial surge protection systems are critical for safeguarding sensitive electronic equipment in industrial settings. One major benefit is the prevention of equipment damage caused by power surges, which can significantly reduce maintenance and replacement costs. Additionally, these systems help minimize downtime, enhancing operational efficiency and productivity. By prolonging the lifespan of machinery and maintaining uninterrupted operations, businesses experience a considerable return on investment. Imagine a scenario where a manufacturing plant experiences a surge–without protection, the delay in operations could be catastrophic, impacting production schedules and client commitments. Moreover, many insurance providers recognize the risk reduction surge protection offers, potentially lowering premiums. Have you considered the impact a power surge could have on your business continuity?

What are common misconceptions about industrial surge protection, and how can they be addressed?

One common misconception about industrial surge protection is that it is only necessary for businesses experiencing frequent power issues or located in storm-prone areas. In reality, power surges can occur due to internal events like equipment switching, making protection essential for all industries. Another misunderstanding is that surge protection is a one-time installation rather than a system requiring regular maintenance and monitoring. Addressing these misconceptions involves educating stakeholders on the unpredictability of surges and the importance of ongoing maintenance to ensure system effectiveness. It’s like servicing your car regularly to avoid breakdowns–surge protection requires similar attention. Have you explored how regular maintenance could optimize your surge protection strategy?

What are some advanced strategies for enhancing industrial surge protection systems?

Advanced strategies for enhancing industrial surge protection include integrating real-time monitoring systems that provide data on surge events, allowing for proactive adjustments. It’s similar to how a smart thermostat optimizes home heating by learning usage patterns. Additionally, companies can employ layered protection approaches, using multiple types of surge protectors–such as AC, DC, and signal line protectors–suited to specific applications. Regular assessments to identify new vulnerabilities and adjusting the protection setup accordingly can further strengthen the system. How often do you evaluate your industrial surge protection measures to adapt to new technological or operational changes?

How can businesses choose the right type of industrial surge protection for their needs?

Choosing the right type of industrial surge protection involves a comprehensive assessment of the facility’s power infrastructure and vulnerabilities. Businesses should consider the types of equipment in use and the potential sources of surges, whether external or internal. For example, facilities relying heavily on DC power should prioritize installing DC surge protectors. Collaborating with experienced professionals can ensure the selection of appropriate devices tailored to the specific needs of the operation. Think of it like tailoring a suit–you wouldn’t choose one off the rack if it doesn’t fit your unique measurements. When was the last time you assessed your surge protection needs?

What constitutes an industrial surge protection emergency, and how should businesses respond?

An industrial surge protection emergency occurs when an unexpected power surge jeopardizes equipment integrity and disrupts operations. This can be seen as akin to a fire drill; quick and efficient response protocols can prevent significant damage and loss. Businesses should have a well-defined response plan that includes immediate shutdown procedures and access to surge protection specialists who can quickly address the issue. Proactive planning and regular drills can ensure everyone knows their role in an emergency. Considering the cost of downtime, how prepared is your business to handle such an emergency?

Resources

- Occupational Safety and Health Administration (OSHA) – OSHA is a government agency dedicated to ensuring safe and healthful working conditions for employees. They provide regulations and guidance on various workplace safety measures, including surge protection.

- U.S. Department of Energy – The Department of Energy focuses on the development and implementation of energy policies and technologies. Their resources can provide insights into energy management and surge protection for industrial facilities.

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory agency of the U.S. Department of Commerce that promotes innovation and industrial competitiveness. They offer valuable research and standards for surge protection in industrial settings.

- Environmental Protection Agency (EPA) – The EPA works to protect human health and the environment. They may offer information on the environmental impact of power surges and the importance of surge protection in reducing energy waste.